Within 28 days, more than 20 thousand TEUs of frozen meat were handled at Paraná’s coast.

In February, TCP (Paranaguá’s Container Terminal) broke the monthly record of reefer container handling. In all, 20,810 TEUs (unit of measure for a 20 feet long container) were handled during the 28 days of the month. The previous record was set in August of 2021 (20,709 TEUs).

These figures represent the handling of more than 268,000 tons of meat. Two types of protein lead the total throughput: chicken (76%) and beef (17%). In comparison to January and February 2022, beef was the one that registered the strongest growth: 280%. In January, the main export destinations were China (20%) and the Arab Emirates (5%).

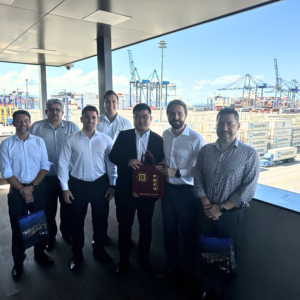

The Brazilian state that stood out the most in the production of beef for export through the Port of Paranaguá was Mato Grosso. According to TCP’s commercial and customer service manager, Giovanni Guidolim, “the flexibility for early entry of cargoes made available by TCP in 2022 increased 5 times the movement of beef from Mato Grosso compared to 2021. This flexibility remains in 2023, further encouraging demand. The state of Mato Grosso is the leader in the production of beef protein exported by TCP, representing 25% of the total”.

The state that produced the most chicken meat for export, passing through TCP, was the state of Paraná. According to IBGE data, in 2021 Paraná was the state that slaughtered the most poultry in the country. Guidolim points out an external factor that influenced the achievement of the export record: “the bird flu recorded in several countries, but not in Brazil, is a factor that increased the global demand for Brazilian chicken. However, this increase in cargo flow was only made possible thanks to our investments in the terminal’s infrastructure”.

Among the investments made is the 43% expansion of the reefer yard. “By the end of 2023, TCP will go from 3,572 reefer plugs to 5,126, the largest number among Brazilian terminals, and the construction of our own power substation to sustain the expansion. Everything to supply the demand of agribusiness and broaden our global portfolio,” explains Guidolim. Other investments are the expansion of the gate (entrance and exit gates for vehicles) and the acquisition of 11 new RTG (Rubber Tyred Gantry) cranes, to be delivered by the end of 2023.

The railroad is another logistical differential of the terminal, being the only one in the south of the country with direct access to the terminal’s customs zone. The railroad is responsible for transporting one in every five export containers to TCP and meets several demands, including 25% of frozen meat exports.

“Currently, the company is a world leader in the export service of chicken meat and the logistical flexibility was a sure bet to meet the market demand. Our large number of regular maritime services, combined with the wide range of logistics modals such as our own warehouses and connections with railroads, allowed TCP to develop logistics flows tailored to customers’ needs”, highlights Giovanni.